There is an abundance of materials available in the world of professional 3D printing. The days when you could only choose from a selection of cheap plastics are long gone. The advent of professional 3D printing has made innovative materials like nylon, stainless steel, carbon fiber and others possible. This method often outperforms traditional fabrication since it allows the creation of almost any geometry quickly and easily, regardless of the material.

More materials are available for 3D printing today than ever before, but choosing which material is best can be a challenge. Choosing the right material is crucial when creating a prototype, tool, or end-use product. In 3D printing, plastic, metal, and composite materials are most common. In addition to plastics, metals and composites are among the most popular materials for 3D Printing Gosford, as they combine the automation of 3D printing with high-performance materials.

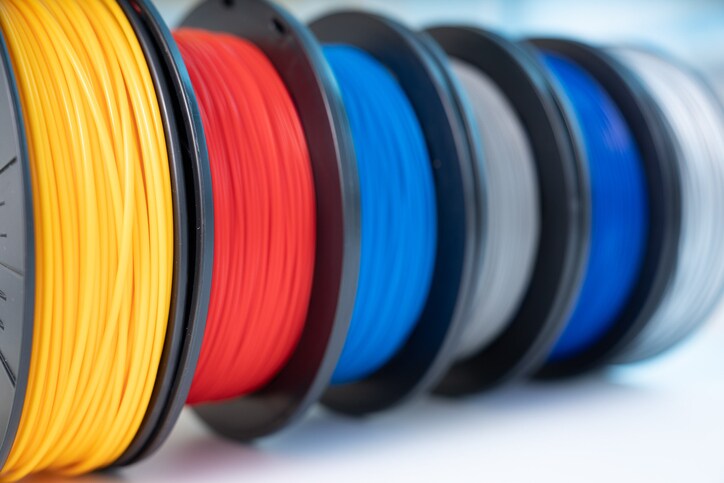

3D printing with plastic

3D printing with plastic provides the most variety of materials, making it the most developed. Professionals who 3D print use ABS, polypropylene, nylon, and thermoplastics like polyetherimide. Although most 3D plastic printing processes require curing and post-processing, they still lead to shorter lead times when compared to traditional fabrication methods.

Acrylonitrile butadiene styrene (ABS): it has good aesthetics as well as a wide range of mechanical properties. The element is used in many everyday products such as toys, kitchen appliances, phones, and more.

The properties of polypropylene (PP) include being chemically resistant, forming living hinges, fire hazard and degradation when exposed to ultraviolet light.

Nylon: Despite being rigid, strong, and durable, they are also expensive and are not resistant to strong acids and bases. This material is typically used in electronic and mechanical components.

Polyetherimide (PEI): A plastic designed to withstand high temperatures during 3D printing. Heat-resistant components and injection mold tools made of this material are quite effective, but the cost is considerable.

3D printing of metal

Metal 3D printing is experiencing a whirlwind of hype right now. Several metal 3D printing firms have emerged in the last few years, offering technologies such as selective laser melting (SLM) and direct metal laser sintering (DMLS). Three-dimensional printing is one of the easiest ways to produce engineering standbys like stainless steel, aluminum, and titanium, which have high strength and durability. Metals printed by 3D printers require some post-processing, but this is less labor intensive than traditional fabrication.

Stainless steel is used in every industry, from architecture to medicine. This versatile, durable material is used for kitchen tools, surgical instruments, and car components. A 3D printer is an efficient and easy way to manufacture these products. Using 3D printing, manual labor is eliminated and speed and automation is increased.

Aluminum is one of the most popular metals because it is lightweight and malleable. Some of the products that are made from aluminum are laptop computers, airplanes, and food packaging. For many aluminum applications, 3D printing has replaced traditional machining.

Titanium is an expensive metal, but it has the highest strength-to-weight ratio of any metal. Besides being durable, tough, and biocompatible, it resists fatigue. However, titanium’s price makes it suitable only for specialized products like high-end automotive parts and surgical implants.

3D printing of composite materials

Recent advances in composite 3D printing have made it possible to create composite parts more easily than ever before. Composites are crafted from reinforcements (like carbon fiber) and matrices (like polymers) to combine the benefits of both. The mechanical properties of composites are superior to those of traditional materials. Engineering professionals who wanted composites’ benefits in the past had to undergo a time-consuming and difficult fabrication process. A composite 3D-printed part can be ready in hours rather than weeks. FEA software is used to optimize parts for their applications voxel-by-voxel with magnetic 3D printing, giving engineers complete control over materials.

Carbon fiber has a better strength-to-weight ratio than any metal. Stronger, stiffer, and lighter products can be made with this material. Aeroplanes, cars, and bikes become more efficient and faster when carbon fiber is used.

Glass is an excellent composite material that is cost-effective. The material can be used for hulls, blades for wind turbines, and circuit boards with high stiffness-to-weight ratios. Glass is a versatile, cost-effective and cost-effective material across multiple industries.

3D printing is becoming increasingly advanced each year. Industry-wide, consumers are shifting away from 3D printing and transitioning into 3D printing for professional and industrial uses, such as prototyping, toys, and tools. Manufacturing has been replaced by 3D printing for many manufacturers. Engineers save time and money by printing prototypes, tools, and end-use parts using 3D printing materials.